5 Use Cases for Oleochemical Pastilles

A complicated and potentially expensive link in any supply chain is the one that connects chemical supply with mixing and manufacturing arms, as the logistics involved in transporting many chemicals can affect overall product quality.

Pastillation simplifies those transitions with a pourable, easy-to-transport form of chemical mixture.

What is a Pastille?

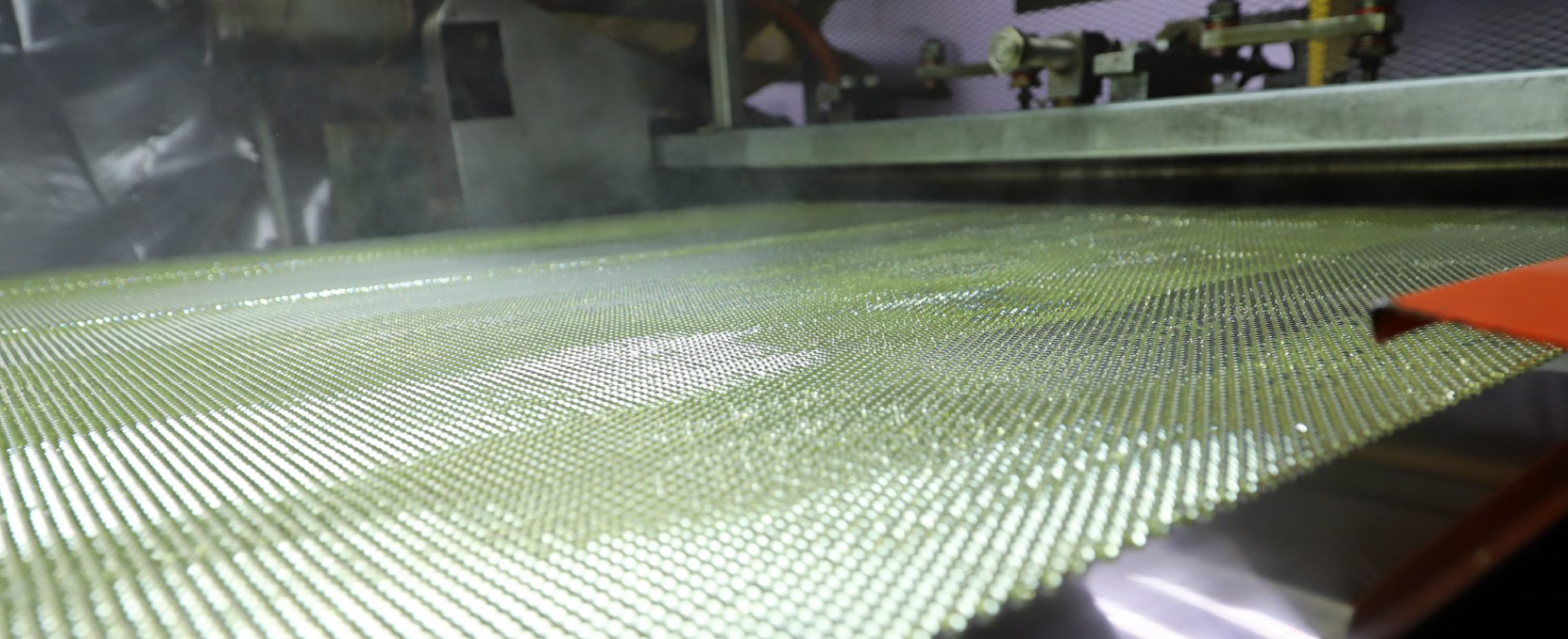

Some products can be converted into a small granule or pellet form called a pastille, which is a split pea-shaped particle formed when the product drips onto a cooling surface and solidifies.

Pastilles offer your customers a convenient and dust-free product that easily flows, stores, and is appealing to the eye. Our experience and technology can make pastilles from 2 to 8 mm in diameter from nearly any difficult-to-transport oleochemical.

With our expertise, we can often process even the trickiest of products, as long as they have the following characteristics suitable for pastille conversion:

- Solid at room temperature

- Ability to melt between 110-300 Fº

- Ability to drip easily

- Crystallize upon cooling within 60 seconds

Contact us for information about evaluation of prospective materials for conversion to pastilles.

5 Pastille Solution Examples

These use cases outline just five of the ways that pastillation will improve your product’s transport and mixing capabilities.

EXAMPLE 1: Operational Efficiency

You currently offer one of your products as a casting in a drum. If your customer does not want to heat the drum to melt and pump the product out of the drum, then pastilles would be a great solution. Your customer can pour pastilles and measure needed weights prior to melting.

EXAMPLE 2: Dust Reduction

You manufacture a product into a fine, dusty powder. Your customer wants less dust, so the operators do not have to wear respiratory protection. Converting the product to pastilles will reduce the airborne dust that causes the hazard. In addition to protecting the health of the workers on the line, the customer also reduces housekeeping effort and cost.

EXAMPLE 3: Reduced Clumping

Your flake product clumps together in the packaging. This causes increased labor and poor efficiency for your customer, and they waste product with the packaging, which reduces their overall ESG scores. Pastilles are less likely to clump and make a better option than flaking for some materials.

EXAMPLE 4: Better Mixing

Your powder product within a solid blend segregates in the packaging during transit. You need a particle size to match that of the other ingredients within the mix. Pastilles come in sizes from two to eight millimeters, allowing for a wide range of sizes to mix better with other products.

EXAMPLE 5: Preference

Your customer wants your product as a pastille. We’ll help your team find the right pastille size and complete the project to your specifications. Our facilities can manage a range of chemicals. Visit our pastillation and flaking page for more information, or contact the team to learn more.